产品中心

铝液冷块板

为工业应用领域提供热解决方案,涵盖电子、发电、数据中心、新能源、汽车、医疗、化工和工程机械。

PRODUCT DESCRIPTION NO. ITEM DESCRIPTION 1 Material Aluminum alloy 3003, 6063,6061 2 Dimension (L*W*T) Up to 500*500*15 mm 3 Cooling Capacity 500 to 1500 W 4 Working Pressure 3 to 4 bars 5 Flatness 0.15 mm 6 Surface roughness 3.2 um 7 Flow rate 5 to 10 L/min 8 Manufacturing Method CNC machining Plus vacuum brazing 9 Joining Method Vacuum Brazing 10 Cooling Method Liquid cooling 11 Surface Finish Mill finish or anodization 12 Coolant Deionized Water,Inhibited Glycol and Water,Dielectric fluid 13 Warranty time 1 year 14 Place of Region Jiangsu province of China 15 Reference Standard GB/T 3190-2008,GB/T 14846-2008,ISO 2768 Metalli’s cold plate technologies include ◆ Vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis ◆ Friction Stir Welded (FSW) performance-fin cold plates and chassis ◆ flat tube cold plates ◆ Press lock Copper tubed cold plates ◆ Vacuum brazed and CNC machined copper cold plates ◆ Stamped and vacuum brazed cold plates ◆ Gun-drilled custom cold plate ◆ Custom channeled cold plate with ladder configuration ◆ Inner-Finned Brazed Cold Plates ◆ Aluminum extruded and welded or brazed cold plate ◆ Aluminum die casting and welded or brazed cold plate ▲ Components for vacuum brazed cold plate ▲ Stamped and vacuum brazed cold plate ▲ Copper tubed cold plate We also supply value added components as below ● Fittings and connectors ● Hoses and tubes ● Heat exchangers or radiators ● Pumps and reservoirs ● Fans ● Other accessories ▲ Radiator ▲ Pump Brief of a liquid cooling system A liquid cooling system is a hydraulic circuit that typically consists of a cold plate that interfaces with the heat source, a pump that circulates the fluid through the system, and a heat exchanger that rejects the heat absorbed by the liquid from the device. A cold plate can be as simple as a copper tube attached to an aluminum plate or they can be extremely complex utilizing multiple technologies to achieve optimized heat transfer. These technologies can include high heat transfer fins, highly engineered micro or meso channels, or varied manufacturing processes such as vacuum, CAB, or dip brazing. Liquid Cooling System Considerations Allowable pressure drop, flow rate, and material compatibility should always be considered when choosing your cold plate and liquid system components. The allowable pressure drop is directly correlated with the pump and the force and flow rate at which it moves the fluid through the system. Materials and fluids need to be compatible through the entire system to prevent galvanic corrosion as well as optimizing your system for your application. ▲ Thermal simulation for cold plate

所属分类:

液体冷却

输入产品详细信息或其他特定要求以获得准确的报价。我们将在24小时内回复。

|

产品描述 |

||

| 序号 | 参数 | 内容 |

|

1 |

材料 |

铝合金3003、6063、6061 |

|

2 |

尺寸(长*宽*T) |

最大 500*500*15 毫米 |

|

3 |

制冷量 |

500 至 1500 瓦 |

|

4 |

工作压力 |

3 至 4 格 |

|

5 |

平面度 |

0.15 毫米 |

|

6 |

表面粗糙度 |

3.2 微米 |

|

7 |

流速 |

5 至 10 升/分钟 |

|

8 |

制造方法 |

CNC加工加真空钎焊 |

|

9 |

连接方法 |

真空钎焊 |

|

10 |

冷却方式 |

液冷 |

|

11 |

表面处理 |

磨光或阳极氧化 |

|

12 |

冷却剂 |

去离子水、抑制乙二醇和水、绝缘液 |

|

13 |

质保期 |

1年 |

|

14 |

原产地 |

中国江苏省 |

|

15 |

参考标准 |

GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli 的冷板技术包括

◆ 真空钎焊或可控气氛钎焊和 CNC 加工性能翅片冷板和底盘

◆ 摩擦搅拌焊接 (FSW) 高性能翅片冷板和底盘

◆ 扁管冷板

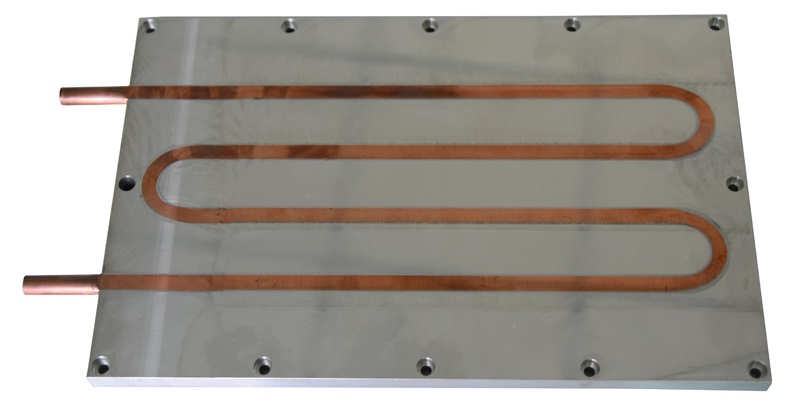

◆ 压锁铜管冷板

◆ 真空钎焊和 CNC 加工铜冷板

◆ 冲压和真空钎焊冷板

◆ 枪钻定制冷板

◆ 带阶梯配置的定制通道冷板

◆ 内翅片钎焊冷板

◆ 铝挤压和焊接或钎焊冷板

◆ 铝压铸和焊接或钎焊冷板

▲ 真空钎焊冷板组件

▲ 冲压真空钎焊冷板

▲ 铜管冷板

我们还提供以下增值组件

● 配件和连接器

● 软管和管道

● 热交换器或散热器

● 泵和水库

● 风扇

● 其他配件

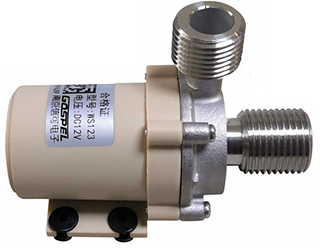

▲ 散热器 ▲ 水泵

液体冷却系统简介

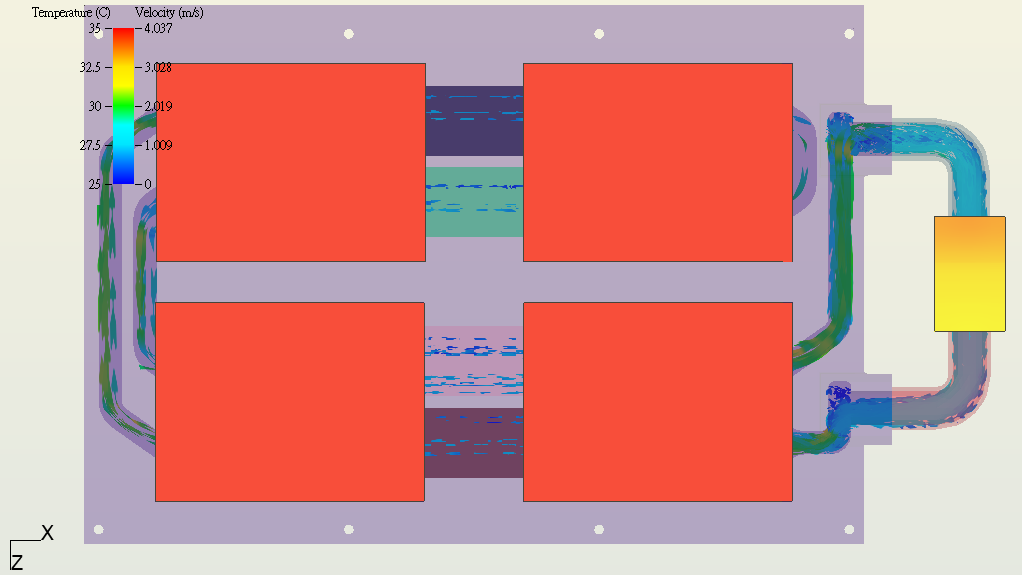

液体冷却系统是一种液压回路,通常由与热源连接的冷板、使流体在系统中循环的泵以及将液体从设备吸收的热量排出的热交换器组成。

冷板可以像连接到铝板上的铜管一样简单,也可以非常复杂,利用多种技术来实现优化的热传递。这些技术可以包括高传热翅片、高度工程化的微通道或细通道,或各种制造工艺,例如真空、CAB 或浸焊。

液体冷却系统注意事项

选择冷板和液体系统组件时,应始终考虑允许的压降、流速和材料兼容性。允许的压降与泵及其使流体通过系统的力和流速直接相关。材料和流体需要在整个系统中兼容,以防止电偶腐蚀并针对您的应用优化您的系统。

▲ 冷板热模拟

key word: